|

Home

|

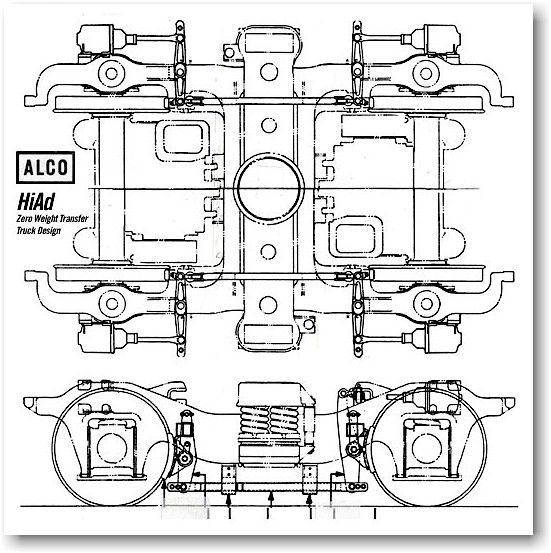

A drawing of Alco's Hi-Adhesion trucks, used on locomotive #315.

Thanks goes out to Charles Tomashek for supplying the description of how HiAd trucks work.

The problem ALCO was trying to solve with the HiAd truck design is a common one. We have all experienced it in our cars. When we were younger we loved to accelerate hard and the hood would rise and the tail of our car would fall, the weight of the car had transferred to the back wheels. For those of us young enough to have had front wheel drive cars, we noticed the same transfer happening. If you have had the pleasure of watching an ALCO Century switch a long heavy cut of cars you would have noticed a massive amount of weight transfer. The AAR type B trucks would transfer weight and swing the side of the truck accordingly, much like an old time drag racer. The HiAd design eliminates most of this transfer and thus the term Zero Weight Transfer truck design. The reason ALCO wanted to eliminate weight transfer is that it causes slipping on the unweighted axles, and thus loss of adhesion and loss of effective tractive effort.

- You will notice the side of the truck frame dips down to Axle level in a graceful curve. This is the most important element of the design, It allows the pushing/pulling forces from the axles to be transmitted in the same PLANE to the bolster. In a type B truck the forces acting on the Bolster were above the plane of the axles and thus the twisting or Yaw in that truck design was considerable.

- The other important design feature was the spring pack location in the center of the truck thus equalizing the weight on both axles using the same principle as an old hand scale.

Compare this drawing to a close-up photo of #315's truck from 1969.